Imagine a vigilant copilot, constantly at your side, ready to intervene and protect at a moment’s notice. That’s the power of Advanced Driver Assistance Systems (ADAS)! They are here to revolutionize road safety and convenience, making driving safer and more enjoyable.

From its inception in the 2000s as a luxury feature to its status today as a growing standard in all vehicle tiers, ADAS technology has proven that top-notch safety is essential, not just a premium option. Its journey from high-end novelty to universal necessity showcases the evolution of automotive safety technology.

This article will take you through the world of ADAS, from its full description to the vital process of calibration that keeps these systems effective and reliable. Prepare to dive into the innovative realm of ADAS calibration technology, led by pioneers like John Bean while exploring the precision that ensures these sophisticated systems function flawlessly, safeguarding your journey every mile of the way.

What is ADAS?

Advanced Driver Assistance Systems (ADAS) represent a significant leap forward in automotive technology, aiming to enhance road safety and improve driving convenience. At its core, ADAS is a set of systems and features designed to prevent and/or reduce the severity of accidents by identifying and tracking objects near the vehicle such as barriers, other cars, and pedestrians.

Primary Functions of ADAS

ADAS functions through a sophisticated network of sensors, cameras, and algorithms to monitor the vehicle’s surroundings, detect potential hazards and, in certain instances, take action to avoid accidents. Its primary function is to augment the driver’s capabilities, providing real-time data and feedback to improve decision-making on the road.

Benefits of ADAS

First and foremost, ADAS significantly reduces the likelihood of human error, which is a leading cause of road accidents. By alerting drivers to potential risks and even taking control of the vehicle in critical situations, ADAS drastically enhances overall vehicle safety. Additionally, ADAS components add a layer of convenience to driving, making long journeys less taxing and everyday commutes smoother and safer.

Common Types of ADAS Technology

Several ADAS technologies have become prevalent in modern vehicles, each designed to address specific driving challenges:

- Forward Collision Warning (FCW): Alerts the driver to an imminent collision with a vehicle or obstacle ahead, providing valuable time to react and avoid potential accidents.

- Lane Departure Warning (LDW): Monitors lane markings and alerts the driver if the vehicle begins to drift out of its lane without signaling, helping to prevent unintended lane changes and collisions.

- Automatic Emergency Braking (AEB): Detects potential collisions and automatically applies the brakes if the driver fails to respond in time, reducing the severity of crashes or avoiding them altogether.

- Adaptive Cruise Control (ACC): Automatically adjusts the vehicle’s speed to maintain a safe distance from the car ahead, facilitating a more comfortable and less strenuous driving experience, especially on long journeys.

By integrating these technologies, ADAS enhances driving safety, reduces the stress of navigating busy roads, and helps to create a more intuitive driving experience.

Understanding ADAS Calibration

ADAS calibration is the precision-driven process essential for maintaining the functionality and accuracy of an Advanced Driver Assistance System. It’s about fine-tuning the sensors and cameras that are the eyes and ears of ADAS, ensuring they can correctly assess the environment around the vehicle and act appropriately.

Calibration and Recalibration: Ensuring Precision and Safety

When a vehicle undergoes repairs, especially after an accident where critical parts like windshields or bumpers are replaced, an ADAS sensor can be knocked out of alignment. Calibration ensures the ADAS components are installed to factory specifications, making sure they can continue to provide reliable data for the vehicle’s safety systems. ADAS recalibration is crucial for restoring sensor accuracy, particularly after physical changes to the vehicle that could affect sensor orientation or functionality.

Meeting OEM Standards

ADAS calibration must adhere to strict OEM standards. These standards ensure that each sensor is positioned and calibrated to provide accurate readings, which is critical for the safety features to function correctly. Even a minor misalignment can significantly impact the system’s effectiveness, highlighting the need for precise calibration.

Types of ADAS Calibration

There are primarily two types of ADAS calibration, each tailored to different requirements:

- Static Calibration: Conducted in a controlled environment, static calibration involves setting up the vehicle in a specially equipped space. The process requires a level floor, specific lighting conditions, and the absence of reflective surfaces to avoid sensor confusion. Calibration targets are used to align sensors accurately. The primary drawback of this type of calibration is allocating the space needed to conduct this work.

- Dynamic Calibration: This type involves calibrating the sensors while driving the vehicle under specific conditions. It ensures that the ADAS can accurately interpret real-world data. The dynamic ADAS calibration process might need clear road markings, certain speeds, and sometimes, the presence of other vehicles to calibrate the system effectively. However, factors like weather conditions and road visibility can limit real world data to the camera, affecting the calibration process.

The Critical Role of ADAS Calibration

ADAS calibration is paramount for the operational integrity and accuracy of the vehicle’s safety systems. This process is not merely a technical requirement, it’s a cornerstone of automotive safety. Proper calibration ensures important ADAS functionalities like automatic emergency braking, lane keep assist, and adaptive cruise control are precise and reliable. This precision is also crucial to avoid system malfunctions or false alerts, maintaining safety and compliance with vehicle manufacturer specifications.

ADAS Sensors that Need Calibration

ADAS relies on a network of sensors to provide critical data for enhancing vehicle safety and driving comfort. These sensors vary in function and placement, each playing a unique role in the ADAS ecosystem. Regular calibration of these sensors ensures the accuracy and reliability of the system.

- Steering Angle Sensors: Steering angle sensors detect the orientation of the steering wheel, influencing ADAS functionalities like adaptive headlights and blind spot detection. Calibration is needed after structural changes or airbag deployment.

- Front Facing Camera Sensors: These ADAS cameras, typically mounted near the windshield, are vital for functions such as automatic emergency braking and lane departure warning. Calibration becomes necessary after windshield replacement or front-end repairs.

- Forward Radar Sensors: Located at the front of the vehicle, these sensors are crucial for adaptive cruise control and forward collision warning systems. They require calibration after modifications to the front bumper or after a collision repair.

- Rear Radar Sensors: Rear radar sensors help with blind spot warning and rear cross traffic alert, needing calibration after rear bumper removal or collision repairs.

- Lidar Sensors: Lidar (Light Detection and Ranging) sensors provide 3D representations of the vehicle’s surroundings, crucial for detecting objects and their distances. Calibration is required when lidar units are disturbed or replaced.

- Ultrasonic Sensors: These sensors assist with parking and maneuvering in tight spaces by detecting nearby objects.

- Wheel Speed Sensors: Part of the ABS system, these sensors also contribute to ADAS functionalities by monitoring the speed of each wheel. They usually need recalibration after brake or wheel hub work.

- Yaw Rate Sensors: These sensors measure a vehicle’s rotation around its vertical axis, aiding stability control and cornering functions of ADAS. Calibration is usually required after suspension or significant chassis work.

Each of these sensors plays a vital role in the overall functionality of the ADAS, requiring precise calibration to function correctly. Regular maintenance and calibration of these sensors ensure that the ADAS operates as intended, providing safety and convenience to the driver.

John Bean ADAS Calibration Systems

In the bustling realm of commercial automotive services, where every second and every detail counts, having the proper ADAS calibration equipment is not just an advantage, it’s a necessity. John Bean solutions are tailored to these high-stakes environments, ensuring that workshops can deliver ADAS calibrations that are not only precise but also consistently reliable and efficient, maintaining the rhythm of high-volume operations without compromise.

EZ-ADAS

The John Bean EZ-ADAS calibration system is a masterclass in calibration efficiency and accuracy, offering:

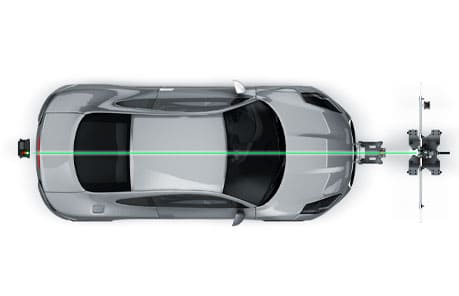

- OEM-Based Centerline Setup: Streamline your calibration process with a system designed to quickly align targets with the vehicle’s ADAS, reducing setup time and increasing throughput.

- Precision Laser Technology: Minimize the margin for error with laser-guided accuracy, ensuring that each calibration is performed to the highest standard.

- User-Friendly Operation: The EZ-ADAS system is designed to be accessible, with straightforward target placement that empowers technicians of all skill levels to perform calibrations confidently and effectively.

The compact design of the EZ-ADAS system, coupled with a wide selection of targets and an optional storage cart, makes it a versatile and space-efficient choice for any workshop looking to enhance its ADAS calibration capabilities.

Tru-Point

For workshops seeking the pinnacle of ADAS calibration technology, Tru-Point offers:

- Full 3D Measurement: Utilize advanced camera technology to obtain a detailed 3D view of the vehicle’s alignment and sensor positioning, ensuring meticulous calibrations.

- Continuous Target Monitoring: Benefit from a system that provides real-time feedback, ensuring the calibration process remains accurate from start to finish.

- Floor Compensation Capability: The Tru-Point innovative design allows for accurate calibration on uneven surfaces, up to 4 degrees, providing flexibility and precision in any workshop setting.

Tru-Point works with any ADAS-capable diagnostic tool and produces detailed validation reports, making it an essential system for workshops committed to delivering the highest standards of service and customer satisfaction.

Empowering Your Calibration Services with John Bean

Choosing the John Bean EZ-ADAS or Tru-Point systems means equipping your business with the best in ADAS calibration technology. These systems not only streamline the calibration process but also ensure that it meets the high standards required by OEMs and safety regulations, making them indispensable tools for any auto service provider serious about offering state-of-the-art ADAS calibration service.

Elevate your service offerings with John Bean ADAS Calibration Solutions and keep your business at the forefront of automotive service technology.

Learn More about John Bean ADAS Calibration Solutions

Conclusion

In our exploration of ADAS and its calibration, we’ve seen the transformative impact these systems have on automotive safety and performance. Precision in calibration stands out as a fundamental requirement, a domain where our expertise shines with solutions like EZ ADAS and Tru-Point systems. These tools don’t just perform calibration; they ensure each vehicle operates at its peak, embodying the latest in safety innovation.

Our commitment to excellence in ADAS calibration is clear. Our technology is not merely about meeting the necessary standards but about setting new ones, ensuring every vehicle is a paragon of safety and reliability. By partnering with John Bean, workshops can not only meet the current demands for ADAS calibration but also anticipate future needs, staying ahead in the automotive industry’s fast-evolving landscape.

Join us in defining the next chapter of automotive safety, where precision meets performance, and innovation drives every journey. With John Bean, your workshop can lead the way in delivering the superior calibration services that modern vehicles require and customers demand.

Contact us today and take a pivotal step towards redefining automotive safety and performance in your calibration services.

The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification  The Complete Guide to Steering Angle Sensors

The Complete Guide to Steering Angle Sensors  Symmetric vs Asymmetric Lift: Which is Best for Your Repair Shop?

Symmetric vs Asymmetric Lift: Which is Best for Your Repair Shop?  Wheel Alignment: Everything You Need To Know

Wheel Alignment: Everything You Need To Know