When it comes to outfitting your repair shop with the right automotive equipment, one of the most important decisions you’ll have to make is choosing between a symmetric lift or an asymmetric lift. Both types of lifts have their own unique advantages and drawbacks, and understanding the differences between them can help you make the best decision for your business.

In this article, we’ll take a closer look at these car lifts, exploring their key features and comparing the pros and cons of each. We’ll also discuss the ideal types of vehicles that work best with each lift and offer tips on how to properly maintain and troubleshoot them. By the end of this article, you’ll be able to make an informed decision on which option is best for your repair shop.

What are Symmetric and Asymmetric Lifts?

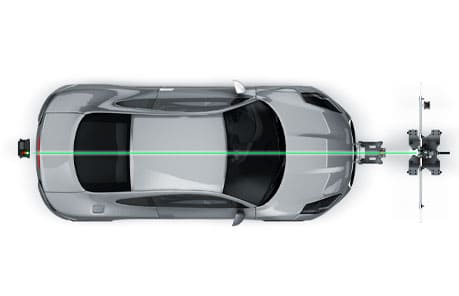

Let’s start by defining these machines and highlighting their key features. Both symmetric and asymmetric lifts are variations of a two-post lift design, meaning the lift uses two parallel columns to hoist the vehicle. Both designs include lift pads that line up with the vehicle’s designated lift points.

Symmetric lifts feature two lift arms on each column that are of equal length. This allows for even weight distribution and makes the lift easy to operate.

On the other hand, an asymmetric lift is designed so that the rear arms on each column are longer and the shorter arms are positioned towards the front of the vehicle. This design allows for uneven weight distribution, which can be more efficient for certain types of vehicles, such as sports cars, exotic vehicles, and FWD trucks or cars.

Symmetric Lift

Pros

One of the main advantages of symmetric lifts is that they are easy to use across a wider variety of cars and trucks. The even lift arm design supports most passenger cars with ease. Although the lifting capacity can vary depending on the specific model and manufacturer, in general, symmetric lifts tend to offer a higher overall lifting capacity and can service vehicles with longer wheelbases such as SUVs and trucks. This is due to the balanced column design, which allows for equal load distribution.

Cons

One of the main disadvantages is that these machines may not be as efficient for certain types of vehicles. The symmetric design can make it difficult to raise or lower vehicles that have unique or uneven weight distributions or shorter wheelbases. Additionally, symmetrical lifts can be more expensive compared to their asymmetric counterparts, which may not be affordable for all repair shop owners. It can also be more difficult to open the vehicle doors on a symmetric lift because the doors are blocked by the columns on either side.

Asymmetric Lift

Pros

The primary advantage of asymmetric lifts is that they are better suited for vehicles with uneven weight distributions, such as sports cars, sedans, and exotic vehicles. By offering longer rear arms, the vehicle can be positioned with more weight on one side of the lift, usually a 70/30 split. The three-stage front arms on an asymmetrical lift provide greater sweep for versatility and ease of spotting. Asymmetric lifts also offer easier access to the vehicle doors because the car is positioned off-center, which ensures that the two lift columns will not block your access. These lifts are also commonly used in shorter bay spaces seeing as the vehicle would not protrude into the front half of the lift.

Cons

There is more complexity in the asymmetric design where the lift arms must be properly aligned, and the machine must be adjusted to match the specific load distribution of each vehicle. Additionally, asymmetric lifts can be more complex to use, which may require additional training for repair shop employees. For example, lifting longer wheelbase trucks can be difficult because of the offset nature of the vehicle. This may require the use of a jack stand under the rear of the truck, and creates a less-than ideal lifting scenario with regards to safety. If your shop does not get many exotic or specialized vehicles, these may not be the right option for you.

Maintenance and Troubleshooting

When it comes to maintaining and troubleshooting symmetric and asymmetric lifts, there are a few key things to keep in mind. First and foremost, it’s important to regularly check for any signs of wear and tear on the lift and address these issues immediately. This includes checking for loose bolts, leaks, and cracks in the lift’s structure. Additionally, it’s important to ensure that the vehicle lift is properly lubricated and that all of the moving parts are functioning smoothly.

It’s also important to follow the manufacturer’s recommended maintenance schedule and to use the correct type of oil or lubricant on the machine. Additionally, it’s a good idea to keep detailed records of all maintenance and repairs that are performed, as this can be helpful when it comes to troubleshooting any issues that may arise. It’s also important to be aware of the lift’s weight capacity and to never exceed it, as this can cause serious damage to the lift and put employees at risk.

Other Types of Automotive Lifts

There are several other types of lifts that are commonly used in automotive repair shops, in addition to symmetric and asymmetric lifts. Some of the most common types include:

- Four-Post Lifts: These are popular for their stability and versatility. They are suitable for most types of vehicles and can be used for a variety of services, including oil changes and tire rotations.

- Scissor Lifts: These lifts use a series of interlocking steel plates to raise and lower the vehicle. They are suitable for most types of vehicles and are commonly used for wheel and brake service, suspension repair and alignment.

- Mobile Column Lifts: These lifts are often hydraulic-operated, providing heavy-duty lifting capacity to handle the most demanding jobs. Unlike traditional fixed lifts, mobile column lifts are portable, with a wireless system that ensures a clutter-free work area—no cables to connect, navigate, roll over, or replace. Each column features an adjustable wheel carriage that adapts to most tire sizes, and an integrated touch screen control console at each column allows operation from any unit. To enhance safety and precision, integrated weight gauges help prevent column overloading and verify lock engagement. Additionally, a wide range of accessories is available to customize your columns further, making them suitable for lifting specialty heavy-duty trucks, transit and municipality vehicles, forklifts, and even facilitating cab removal for standard pickup trucks.

Each type of lift has its own set of advantages and disadvantages, and the choice of which option to use will depend on the specific needs and size of the repair shop.

Conclusion

In conclusion, symmetric and asymmetric lifts can both be important pieces of shop equipment. Each type of car lift has its own unique features and advantages, and the choice between the two will depend on the specific needs of your business.

Symmetric lifts are easy to use, require less maintenance, and are suitable for a wide range of vehicles, including sedans, SUVs, vans, and trucks. On the other hand, asymmetric lifts are more efficient for certain types of vehicles, such as sports cars and FWD vehicles.

When considering which type of auto lift to purchase, repair shop owners should carefully consider their specific needs and the types of vehicles they will be working on.

View our line of premium Auto Lifts below to find the best machine for your shop today.

The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification  The Complete Guide to Steering Angle Sensors

The Complete Guide to Steering Angle Sensors  Wheel Alignment: Everything You Need To Know

Wheel Alignment: Everything You Need To Know  The Complete Guide to ADAS Calibration

The Complete Guide to ADAS Calibration