WHEEL BALANCERS

HIGH QUALITY WHEEL BALANCING

& NO TOUCH DIAGNOSTICS

ACHIEVING OPTIMAL WHEEL BALANCE

Today’s modern vehicles are engineering marvels that push the performance and efficiency limits to the max.

An integral part of achieving high-performance and maximum fuel economy is a properly balanced set of wheels and tires that offer a secure grip in all weather conditions and perform well at a variety of speeds.

As a wheel rotates, its weight must be precisely and evenly distributed because even the tiniest of variances in wheel weight distribution can lead to harmful vibrations and uneven tire wear.

Professional wheel balancers from John Bean® help identify areas on a wheel that are out of weight balance and allow technicians to quickly correct issues.

Long Term Customer Satisfaction

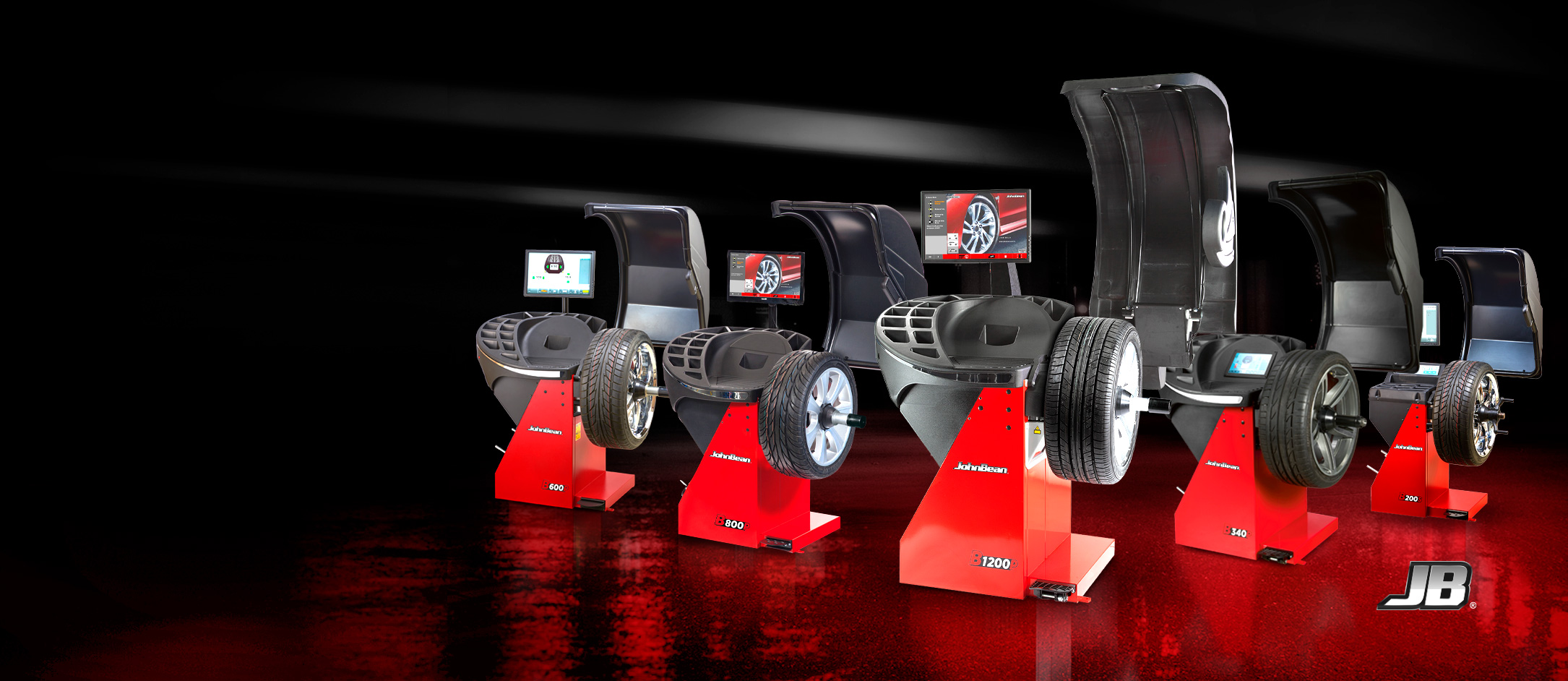

Dynamic and Static Wheel Balancers

There are two types of wheel balancer machines on the market today; dynamic and static. The difference between these two machines comes down to wheel motion. On static machines, the wheel is balanced without moving or spinning. Dynamic wheel balancer machines, like those offered by the professionals at John Bean, simulate the motion of a wheel as it is spinning on your vehicle. Balancing a wheel in motion allows for a higher degree of accuracy than a static measurement and ensures that your customers will receive a positive driving experience. Modern machines also make this process remarkably quick and easy for tire technicians.

Accurate Weight Correction

In order to properly balance a wheel, professional wheel balancers must identify the exact location of wheel imbalance with a high degree of accuracy and be able to quickly convey this information to technicians. Modern machines, like the John Bean series of wheel balancers, use a combination of laser precision and video technology to show the exact location where weight must be placed in order to properly balance the wheel. This process speeds up productivity drastically, allowing your tire shop to get more customers on the road in less time.

Runout - A Costly Problem

Although tires and wheels are precisely manufactured, inaccuracies in the production process can lead to high spots and low spots on a tire assembly known as runout. Although a tire may appear in balance on more basic machines, vibration and driveability issues can still occur after a customer hits the road. Advanced wheel balancers like the John Bean B2000P can detect run-out with advanced sensors that take hundreds of thousands of measurement points with a resolution of 0.004” (0.1mm) to create a 3D model of the tire and wheel assembly. This allows your technicians to compensate for runout with precisely placed wheel weights that counteract the negative effects.

Speed = Productivity = Revenue

At John Bean, we know that time equals money and that’s exactly why we’ve created a series of wheel balancers with features that are designed to get the job done quickly, and with a high degree of accuracy:

- Touchscreen and/or full color user interface

- Laser pointed weight placement (easyWeightTM)

- 3D Automatic balance measurement

- Automatic spoke detection

- Split weight capability

- Automatic wheel clamps (Power ClampTM)

- Automatic wheel data entry

- Automatic wheel stop for weight placement

- LED wheel lighting for optimal visibility during rim cleaning and weight placement

FAQs

When purchasing a wheel balancer, you’ll need to consider the following:

- How easy is the machine to use? How durable are the components?

- How quick is the balancing process?

- What kind of volume does your shop produce?

- What’s your budget?

- How quick can someone be trained to use the wheel balancing machine?

Static balancing is accomplished while the wheel is at rest. Dynamic balancing is accomplished while the wheel is in motion. Dynamic balancing is a much more accurate measurement due to the simulation of operating speeds.

Wheel balancing can address customer complaints such as vibration and uneven tire wear. These conditions can also put additional stress on other components of a vehicle, such as the suspension, which can lead to customer complaints.

Runout occurs when there are high spots and low spots on a tire assembly that can lead to the wheel not being perfectly round. Runout can be accommodated by carefully installing wheel weights to counteract the negative effects of runout. This is possible with machines that measure wheels with an incredibly high degree of accuracy.