OEM TRUSTED EQUIPMENT: ACURA | BUICK | CADILLAC | CANOO | CHEVROLET | CHRYSLER | DODGE | GENESIS | GMC | JEEP | RAM

V3300 Diagnostic Wheel Alignment System

Work faster and smarter with the John Bean® V3300 Diagnostic Wheel Aligner.

The V3300 is a stand-alone wheel alignment system that utilizes advanced technology to guide technicians of all skill levels through the wheel alignment process. We’ve combined the fastest camera system ever offered by John Bean with advanced notification alerts and clever software flow to reduce alignment errors, as well as decrease overall alignment time.

This means you can push more alignments through with fewer errors; drastically increasing your productivity and boosting your revenue. The V3300 is the ultimate in wheel-alignment technology.

AVOID ERRORS

The advanced notification system on the V3300 instantly recognizes any error made during the alignment process and allows technicians to instantly correct the error during the alignment operation procedure. From suspension stress to uneven rack surfaces and loose components; the V3300 eliminates alignment errors and speeds up the entire alignment process.

REAL-TIME SUPPORT

Looking for real-time support? The V3300 goes beyond wheel alignment to offer critical, real-time data from OEM’s such as repair information, TSBs, recalls, and TPMS reset procedures. This means less time searching for resources to get the job done right and more time pushing alignments through your shop.

ADAS INTEGRATION

ADAS calibration is a consistent reality for modern shops that perform alignment procedures on their customer’s vehicles. Performing ADAS calibration accurately can be a constant source of productivity issues due to the sheer variety of procedures and the ever-changing OEM calibration requirements. The V3300 makes this task easy with real-time information on vehicle-specific ADAS procedures. Combine the V3300 with the John Bean Tru-Point™ recalibration system for ultimate productivity.

VERSIONS

V3300 AC400 (EEWA552BV2):

This version includes the AC400 wheel clamps.

V3300 AC200 (EEWA552HV2):

This version includes the AC200 wheel clamps.

Features

COMPACT CONSOLIDATED DESIGN

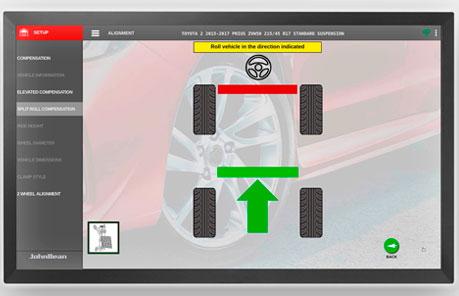

FAST COMPENSATION AND OPTIMIZED ALIGNMENT FLOW

DRIVE-ON AID

Built-in camera that allows the operator to view the vehicle as it being driven onto the lift, ensuring proper loading for alignment procedures.

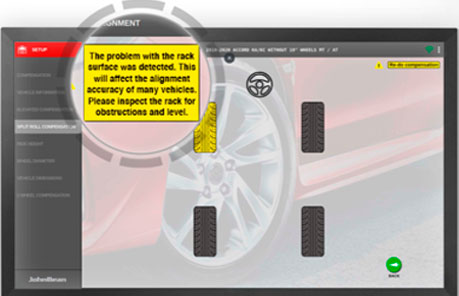

ADVANCED NOTIFICATION SYSTEM

The advanced notification system provides critical information without slowing down the alignment process, automatically detecting and compensating suspension stress issues or environmental errors, only notifying the technician when necessary to provide additional information for corrective action.

VIDEO: SEE IT IN ACTION

ADDITIONAL FEATURES

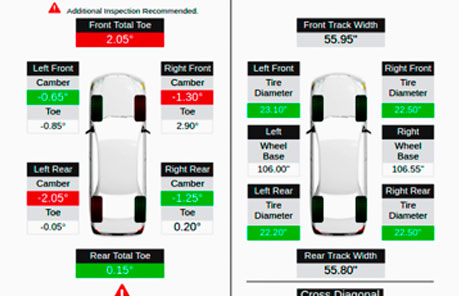

AUDIT MODE

Quickly uncover extra service opportunities with alignment audit reports. This report includes measurement of track width, front and rear toe, camber, wheelbase, wheel diameter, and cross dimensions.

Automatic camera tracking eliminates the need to readjust the camera after raising the lift, while a continuously calibrating third camera retains ultimate accuracy.

Eliminate manual data entry, speed up measuring, and increase accuracy using our specially designed, optional Ride Height Targets.

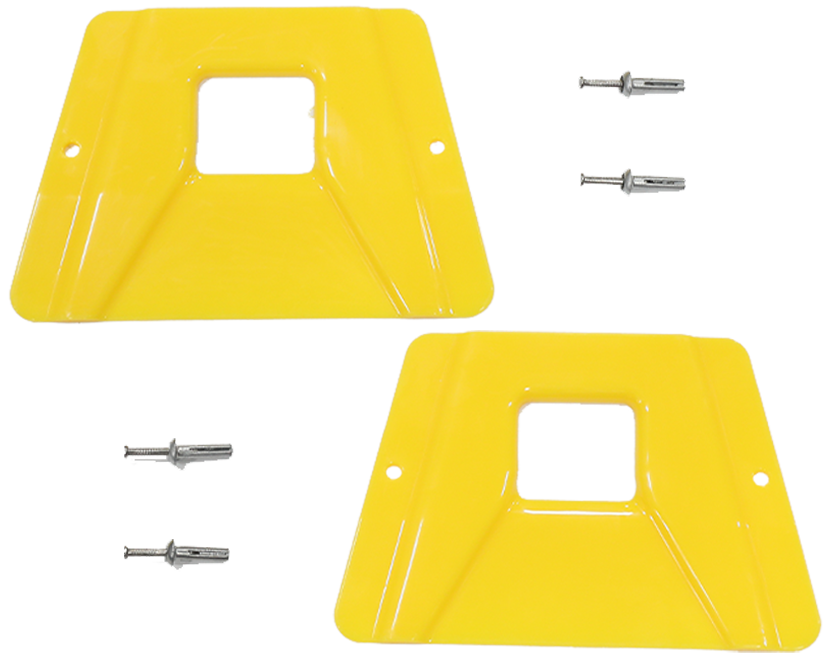

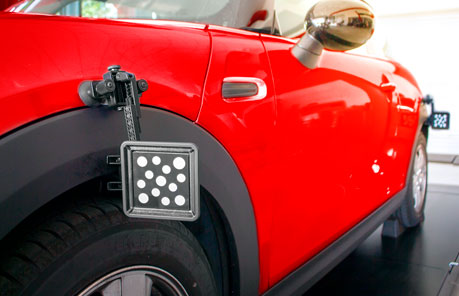

AC400 CLAMPS

AC200 CLAMPS

Fast and easy to use with self-centering design, two-sided claws provide reliable clamping, even over hub caps.

ADJUSTMENTS

- EZ-Toe

- A-Arm

- Cradle

- Single Tie Rod

- Drag Link

- Toe Curve

- Elevated

- Help Videos

- Parts Calculator

- Parts & Tools

- Wheels Off

MEASUREMENTS

- SAI

- Max Turn

- Toe Out On Turns

- ROMESS - OPTIONAL

- TIP Target Ride Height

- Frame Angle

- On-Demand Ride Height

ACCESSORIES

STANDARD

OPTIONAL