OEM TRUSTED EQUIPMENT: CHRYSLER | DODGE | GENESIS | GMC | HYUNDAI | JEEP | KIA | MERCEDES-AMG | MERCEDES-BENZ | MERCEDES-MAYBACH | RAM | RENAULT | SMART | TESLA

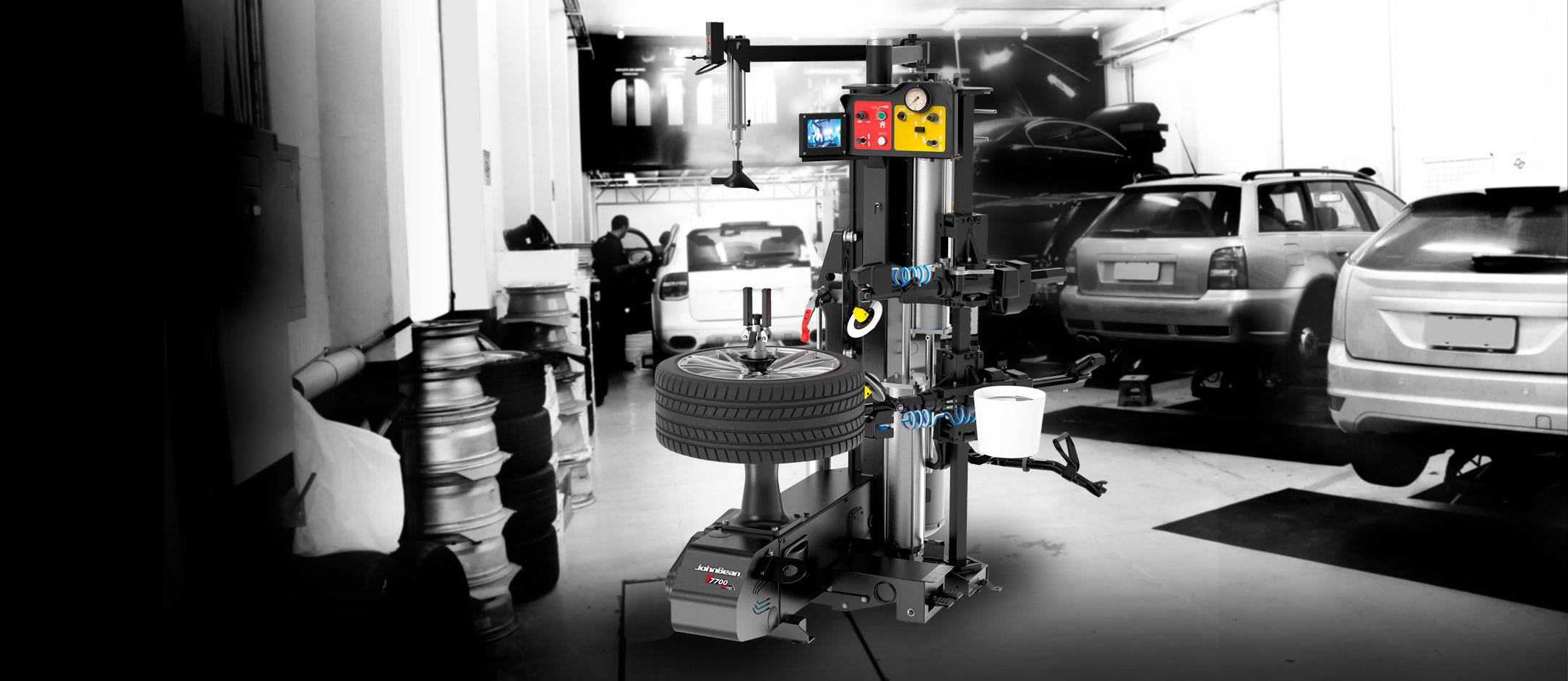

T7700G Leverless Tyre Changer

Maximize shop productivity and work on a wide range of specialty, run-flat, low-profile, and high-performance tyres with the John Bean® T7700G tyre changer.

Changing tyres on modern vehicles that utilize low-profile or run-flat tyres can be a challenge for shops that are not properly equipped, due to the potential for wheel damage. The John Bean T7700G leverless tyre changer provides a comprehensive set of tools that make changing a wide variety of tyres quick and easy while minimizing the chance of wheel damage.

Easily move tyres into position with a pedal-operated wheel lift and secure the wheel with an innovative center post clamp that can accommodate a wide variety of wheels and tyres. The Dynamic Bead Breaker system utilizes two synchronized disks that adjust with pneumatic precision to practically eliminate wheel damage and make short work of removing ultra-high-performance and run-flat tyres. Our powerMONT™ tool makes mounting and demounting tyres a snap.

For high-volume and specialty shops, this is the ultimate productivity workhorse.

Versions

T7700B 2S (EEWH574AE2): Lower bead operation is monitored by a mirror and a top-side bead seating kit is not included.

Features

POWERMONT™

PROSPEED™

DYNAMIC BEAD BREAKER

LOWER BEAD CAMERA VIEW

ADDITIONAL FEATURES

CONTROL PANEL

PNEUMATIC BEAD PUSHER

The Pneumatic Bead Pusher assists in the mounting process of the upper bead. Its dual-purpose design offers a reverse-side hook to help lift heavy tyres.

TOP-SIDE BEAD SEATER

CENTRE-POST CLAMP

The centre-post clamp design has numerous benefits, most important is the drastically reduced risk of wheel damage and less clamping restriction than the turntable design.

TECH SPECS

Part Number

EEWH574AE3 – T7700G 2S

EEWH574AE2 – T7700B 2S

Max Rim Diameter

30″ | 76cm

Max Tyre Width

15″ | 38cm

Max Rim Width

13″ | 33cm

Max Wheel Diameter

47″ | 119cm

Wheel Lift Capability

154 lbs. | 70 kg

Power Supply

230V 1ph 50-60Hz 16A

Air Pressure Required

116-174 PSI | 8-12 bar

Dimensions HxWxD

75″x63″x78″ | 190x160x198cm

ACCESSORIES

STANDARD

optional