OEM TRUSTED EQUIPMENT: CHRYSLER | DODGE | JEEP | KIA | MERCEDES-AMG | MERCEDES-BENZ | MERCEDES-MAYBACH | RAM | SMART

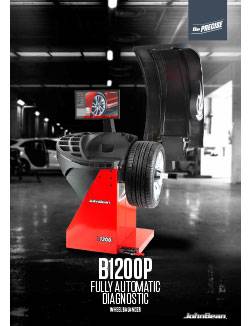

B1200P Automatic Diagnostic Wheel Balancer

Built with the ultimate precision to assist technicians looking for perfect wheel balancing, the B1200P from John Bean® is the ideal choice to boost productivity and revenue in your wheel service.

Working on modern vehicles requires the right equipment that can precisely diagnose weight and shape defects and indicate wheel vibration issues that can lead to customer dissatisfaction.

The B1200P is a fully automatic machine equipped to detect rim diameter, offset distance, wheel and rim radial runout, and to suggest matching mounting for optimal wheel balancing results. Additionally, it automatically selects the appropriate balancing mode, weight type, and placement, requiring no manual intervention from a technician.

Features like easyWeight™ technology utilise laser-guided precision to show the exact location of optimal weight placement. Balance high-performance wheels with confidence and ensure a better appearance of the wheel with our Split Weight Mode that allows for accurate balancing of alloy rims while hiding the weights behind the spokes. Productivity-enhancing features like wheel measurement scanning, automatic spoke detection, and electromechanical Power Clamp™ provide pinpoint accuracy and efficiency.

The B1200P wheel balancer from John Bean is simple to operate and provides state-of-the-art diagnosis with unique attributes to make every wheel balancing job easier and more accurate than ever.

Features

RADIAL AND LATERAL RUNOUT

Provide a complete diagnosis of the assembly uniformity and display the radial and lateral runout measurements from the first to the third harmonic, indicating wheel assembly possibilities and pinpointing balancing issues.

AUTOMATIC SPOKE DETECTION

The laser scanner automatically detects the number and position of rim spokes for the system to indicate weight placement behind wheel spokes and allow for split weights.

EASYWEIGHT™

Take the guesswork out of weight placement; this pinpoint accurate system uses a laser to show the exact spot to place a weight to ensure precise balancing.

POWER CLAMP™

The electromechanical power clamping device always clamps the wheel accurately with a constant force and provides a reliable and consistent condition to assure accurate and repeatable measurements.

ADDITIONAL FEATURES

TOUCHSCREEN INTERFACE

Fast and intuitive interface with large digits, colored weight position indicators increase speed, ease-of-use, and ergonomics for the daily job.

AUTOMATIC DATA ENTRY

No manual data entry is required; this machine automatically detects the wheel dimensions and selects the balancing mode, weight type, and weight position to speed up the balancing cycle time and minimize operational errors.

SMARTSONAR™

Automatic rim width detection using sonar sensors to avoid manual entry errors.

SPLIT WEIGHT MODE

This feature allows for accurate balancing with easy-to-follow manual procedures to hide the weights behind the spokes, preserving the wheel’s visual presentation.

STOP IN POSITION

Touch the screen to automatically rotate the wheel to the weight application position.

RIM LIGHTING

Bright LED lighting system that facilitates rim cleaning and aids in the weight positioning process.

QUICKBAL™

Optimizes the number of revolutions according to each wheel’s specifications while always operating at maximum speed and reducing cycle time.

PRINTOUT

Reports can be printed through the local network or saved as a PDF to an external flash drive.

TECH SPECS

Part Number

EEWB567AE1

Wheel Clamping

Power Clamp™

Automatic Rim Diameter Range

14″-26″ | 36-66cm

Automatic Rim Width Range

3″-15.8″ | 8-40cm

Automatic Scanner Offset Range

4.7″-16.3″ | 12-41cm

Manual Rim Diameter Range

8″ – 32″ | 20-81cm

Manual Offset Range

1″ – 20″ | 3-51cm

Manual Rim Width Range

1″ – 20″ | 3-51cm

Max Wheel Diameter

42″ | 107cm

Max Wheel Weight

154 lbs. | 70 kg

Power Supply

230V 50/60Hz

Dimensions HxWxL

75″x39″x53″ | 190x100x136cm

Net Weight

238 lbs. | 135 kg

ACCESSORIES

STANDARD

OPTIONAL