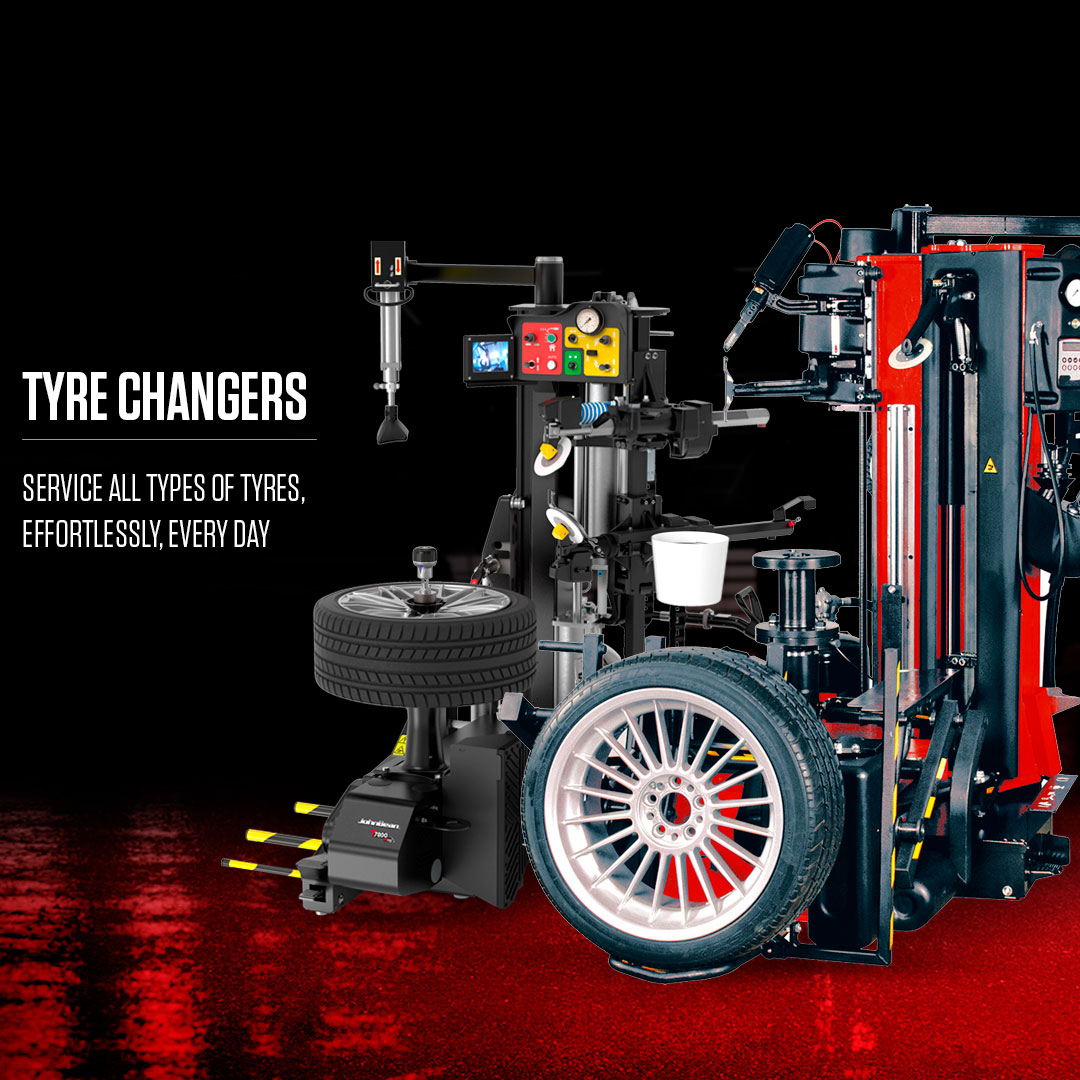

TYRE CHANGERS

SERVICE ALL TYPES OF TYRES,

EFFORTLESSLY, EVERY DAY

MODERN VEHICLES DEMAND MODERN TECHNOLOGY

The core of any high-volume tyre shop is the efficient mounting of tyres on the wheels of your customer’s vehicles.

Today’s modern cars and trucks run a variety of wheel and tyre combinations that can be a challenge for machines that are not up to the task.

Professional tyre changers can handle a variety of rim widths and tyre types, and are designed to help you increase your shop’s overall productivity with a combination of speed, versatility, and safety.

Whether you service municipal fleets or own a high-volume automotive repair shop – there’s a tyre changer to fit your unique needs.

INCREASE PRODUCTIVITY, SAFETY, AND PROFITABILITY

TYRE CHANGERS FOR EVERY TYPE OF SHOP

John Bean® offers the following types of tyre changing machines to meet the needs of your shop.

LEVERLESS TYRE CHANGER

CENTER-POST TIRE CHANGER

Designed for ease-of-use by technicians of all skill levels, center-post tire changers offer speed and precision for efficient tire-changing operation. With less clamping restriction than a turntable design, the risk of wheel damage is drastically reduced. An anti-rotational pin allows the center-post clamp to accommodate a wide range of wheel sizes, and the pneumatic bead assist enables efficient single-operator mounting and demounting of the upper bead. For high-volume tire shops that need a tire changer machine with optimum technology, the center-post design is a definite game changer.

TILT TOWER

FEATURES THAT INCREASE PRODUCTIVITY

John Bean tyre changing machines are designed with various features to keep operators safe and allow them to perform their job with ease, including:

- Fast, Accurate Wheel Clamping

- Lower Bead Camera Assistance

- Easy Bead Breaking For Low Profile and Run-Flat Tyres

- Easy Mounting and Demounting

- User-Friendly Controls

- Precise, Safely Located and Ergonomic Foot Controls

- Integrated Pressure Limiter

- Wheel Protection

FAQs

When making the commitment to purchasing a tyre machine, you should consider the following:

- How many vehicles does your shop service in a day?

- What type of vehicles do you regularly work on?

- Do you work on run-flat and low profile tyres?

- What’s the experience level of personnel in your shop?

- What’s your budget?

John Bean® offers five types of tyre changing machines:

- Leverless

- Tilt Tower

- Center-Post

- Swing Arm

- Heavy-Duty

Each type of wheel service equipment has a distinct set of advantages but all of these options make changing tyres easy and profitable.

Leverless tyre changers can work on nearly any type of wheel/tire combo with speed, precision, and low operator fatigue. Due to their higher cost over other machine variants, leverless machines are great for high-volume tire shops that will see a large enough productivity boost to justify the higher cost.

Since a tilt tower mechanism allows easy access to the turntable and returns to the same location each time; this design is perfect if your shop regularly works on larger wheels and tyres with a higher level of volume.

For smaller shops with lower wheel service volume or shops looking to stay on budget; swing arm machines work on a wide variety of wheels but require a bit more labor and a bit more adjustments on the fly during each tyre change.

For commercial vehicles or extra large wheels, a heavy duty tyre changer offers a rugged design and wide clamping range that can handle rims between 14 and 58-inches.

UHP stands for Ultra High Performance and designates tyres that have an ultra-low profile (sidewall thickness) and are typically found on high-performance vehicles. RFT stands for Run Flat Tires and designates tires that can run for a preset distance with little to no air left in the tire itself. Each of these designs poses a challenge to properly mount and dismount due to the stiffness of the sidewall.